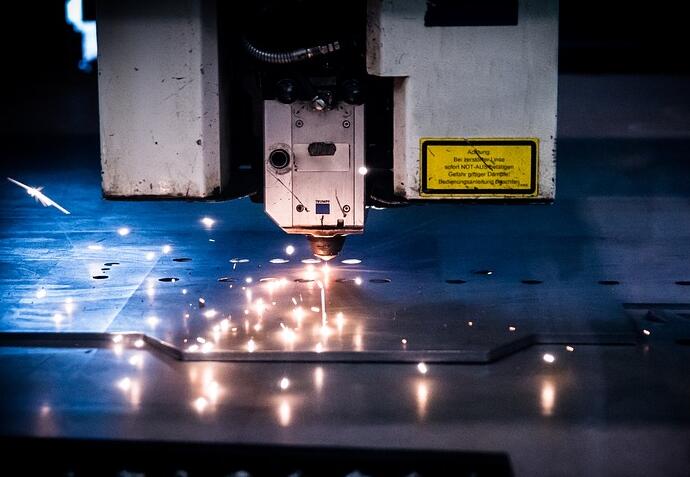

其實(shí)我們都知道激光切割機(jī)在切割各類特殊材質(zhì)的金屬時(shí),需要添加輔助氣體與材料在高溫下產(chǎn)生化學(xué)反應(yīng)來(lái)增加切割速度。下面就給大家簡(jiǎn)單了解一下吧。

In fact, we all know that laser cutting machines need to add auxiliary

gases to produce chemical reactions with materials at high temperatures to

increase cutting speed when cutting various special materials of metal. Let's

give you a brief introduction below.

激光切割機(jī)對(duì)于1mm以下的銅板,完全可以不用輔助氣體;

The laser cutting machine can completely eliminate the need for auxiliary

gas for copper plates below 1mm;

其次切割機(jī)對(duì)于1mm-2mm的銅板,建議選擇氮?dú)庾鳛檩o助氣體;

Secondly, for copper plates with a thickness of 1mm to 2mm, it is

recommended to choose nitrogen as the auxiliary gas for the cutting machine;

激光切割機(jī)對(duì)于2mm以上的銅板,建議選擇氧氣作為輔助氣體。

For copper plates larger than 2mm, it is recommended to choose oxygen as

the auxiliary gas for laser cutting machines.

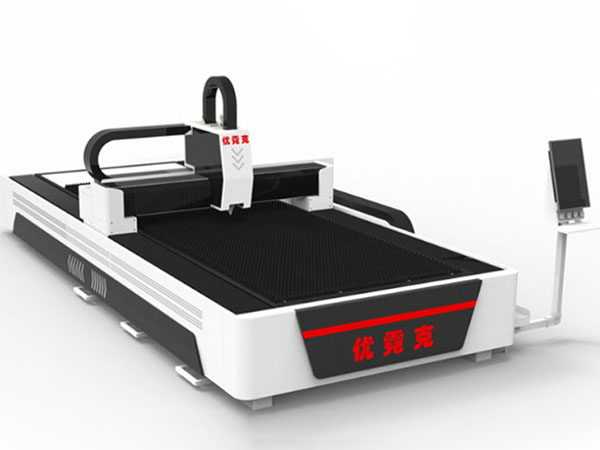

激光切割機(jī)的使用都是跟空氣壓縮機(jī)緊密相關(guān)的,壓縮空氣的品質(zhì)對(duì)激光切割質(zhì)量有非常直接的影響。

The use of laser cutting machines is closely related to air compressors,

and the quality of compressed air has a very direct impact on the quality of

laser cutting.

總的來(lái)說(shuō),激光切割機(jī)通過(guò)氣體來(lái)增加切割效率的效果是非常好的,歡迎大家前來(lái)咨詢了解更多小技巧,相信對(duì)大家一定會(huì)有幫助的。